As the weather in North Carolina has started its harsh descent into winter, progress has gotten slower on the 850R. Many of the projects still left on the car are either too time consuming, or require a professionals touch (like the interior headliner). We have started working on acquiring parts for a performance upgrade that should give the 850R a bit more power. This process involves using an intake manifold from a naturally aspirated 850, and the throttle body off of a 960. As luck would have it, our local LKQ had both of these cars in (well actually we already knew that from when we had to get the new caliper). Removing the parts was easy, and while Steve and Andrew set about on removing the intake from the 850 wagon, I began the process of removing the tail lights to replace the old, beaten, faded tail lights currently installed on our 850R.

The rear of the 855 after removing the tail lights.

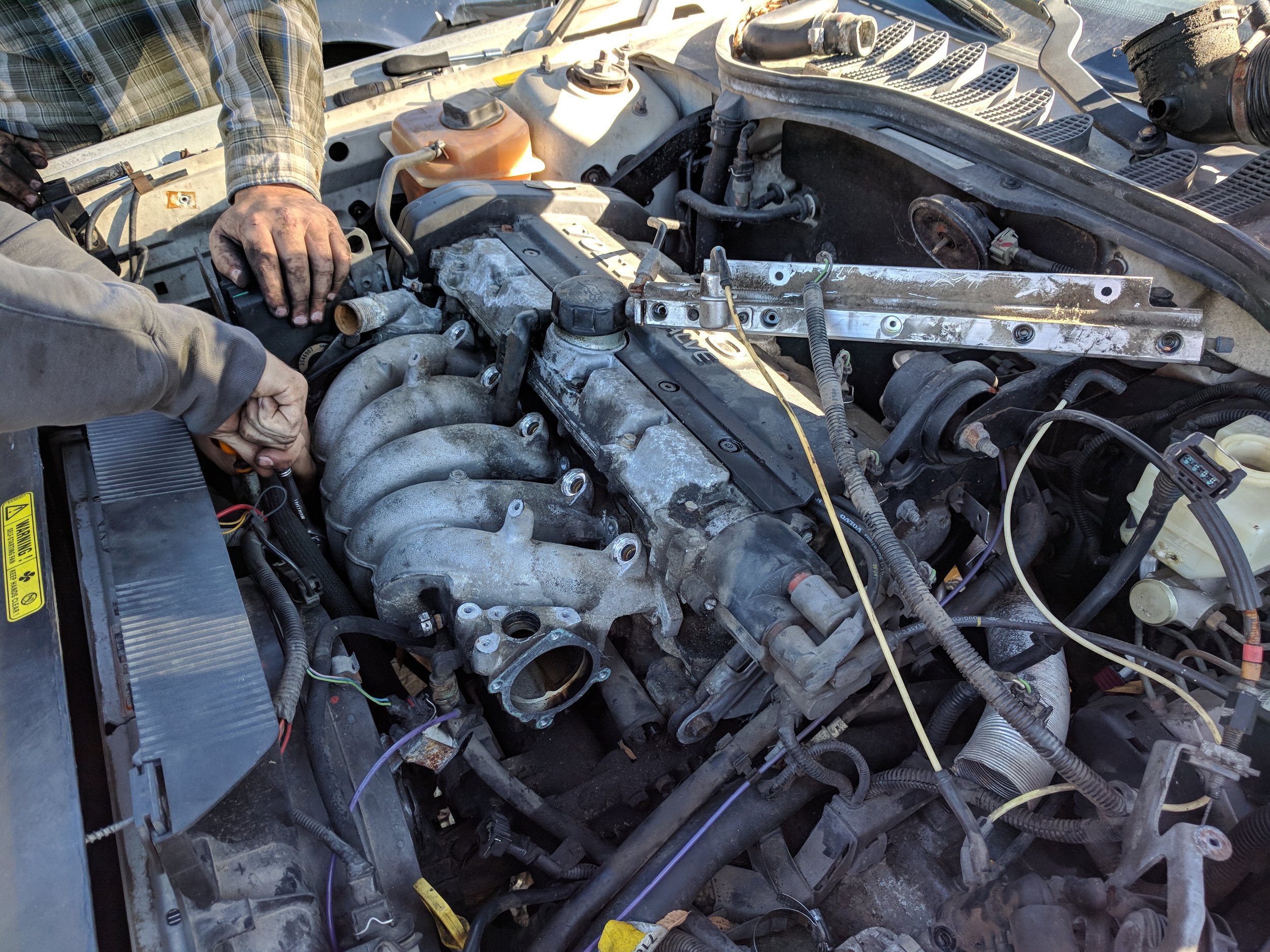

Removing the intake from the 850 was a standard affair, and while I did not take part in the removal, the process only took about 20-30 minutes. The use of an extremely lengthened wrench was needed to remove some trick bolts, however with the tool kits we brought along we had no issue getting each bolt out.

The naturally aspirated 850 features a larger, higher bore, intake manifold allowing for better airflow over the stock turbo intake manifold.

Working on removing the pieces around the intake manifold for removal.

Our haul of parts from the 850. We are also able to take the ECUs from the engine bay.

With all the parts collected, we moved on to the Volvo 960 that was also in the yard. Thankfully for us the car was only 1 row over, and was almost completely untouched. On this car the only part that we needed was the throttle body. The throttle body from the 960s 6cyl engine has a larger diameter inlet, and will allow us to increase airflow. This increase in air flow from both the new throttle body and intake manifold will create a good starting point for a performance tune on our 850Rs engine. The one down side of this modification will be the need to have the car dyno tuned to properly match the air/fuel ratio. If we can not achieve this, expect to see these parts in the Volvo Parts section of the website!

Steve and Andrew working on removing the throttle body from the 960.

With the warm patch of weather we should be able to install the new tail lights and interior trim pieces. Stay tuned as we continue to build and work on this amazing project!