VDASH Pt. 1 - A new tool for a modern Volvo hacker

Owning a 2012 P3 S60 means that there are a lot of features that were added to later models, or removed from the car for the US market. Some of these features include remote start, remote window controls, and even automatic headlights. Luckily there is a tool to add these features in, and it is called VDASH. VDASH is a program that connects through a Volvo DiCE system to crack the CEM and modify options on the car. The program is ‘payment” based, and requires a few hundred dollars to unlock all of the options you will want to add. For reference, remote start, TFT digital dash modifications, and auto headlights costs around $40 in options from VDASH, a far departure from the hundreds of dollars a dealer would charge just to add remote start.

For my car, I was able to add in remote start, window key controls, and auto headlights (with the addition of the appropriate parts, but I will get into that later).

Part 1 - Installation and Setup

Before we begin, you are going to need the following equipment:

Windows PC, preferably with a decent CPU

Volvo DICE Tool, these can be found on AliExpress for around $80, and can be helpful for DIY projects such as this as well, as diagnostics with Volvo VIDA.

Battery Tender (capable of over 7A)

VDash Software, download from D5T5

I have made a copy of the VDASH folders available as a downloadable ZIP

Once you have installed the program, you will be asked to make an account. Unless you are a shop, you are best served with the free account not the subscription. Connecting to your car is as easy as plugging into the OBD2 port with your DICE connector, and plugging its USB connector into your laptop. If everything is ready to go the program will be able to read data from your car and it will show up on the bottom of the screen.

If you are planning to crack the CEM, connect your battery charger beforehand! This process can take a while, and it will automatically stop reading your CEM if the battery charge falls too low. Since I was using an outdoor plug, I made sure to also buy an extension cord with a 3 female end. This way I could have my battery charger and laptop plugged in for the process.

I used a Black & Decker car battery charger that had a peak charge of 15A, with the ability to do 40A. It had a nice screen that showed the battery percentage, as well as charge rates.

Part 2 - Running VDASH & Cracking the CEM

Once you have connected your PC to your car, it should be fairly obvious in the VDASH program that it is working. You will get multiple different readouts from the vehicle. From here you can go to the lower right corner to the button that says Decrypt CEM. This process can take a while, and can be affected by your CPU speeds. (So your old dual core HP may not be the best choice!) You will also need a stable connection from the PC to the internet, as your progress is saved online, and data is transmitted to the VDASH developers. I highly recommend you start this process at night, as your car will not be drive-able while the program is working. You can stop the process at any time, and pick up where you left off. I left my DiCE unit hanging in a location that I could see the lights blinking. If you see that none are blinking during the brute force crack, then the process has either stalled for some reason, or it is done. For my personal car, I actually used my desktop computer which allowed me to finish in around 6 hours.

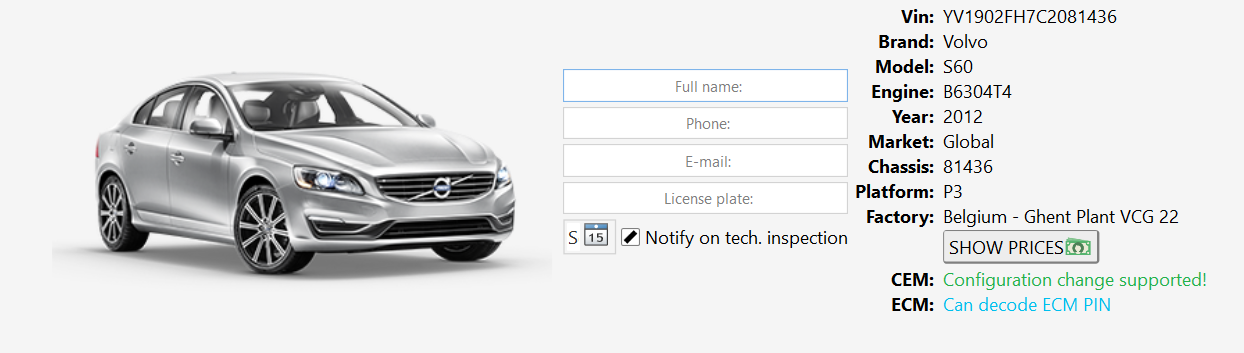

This is the screen you should get when the car is connected. (Where mine says CEM: Configuration change supported will show an UNLOCK CEM button, for those cars that are not unlocked yet).

My desktop has a i7 5820k (6 cores), which allowed me to brute force this decryption much faster.

Once the process is complete, we can now go into VDASH and begin to configure car settings. I will be covering all of my mods in part 2 of this write up. I will be covering things such as auto headlight installation for 2011 and 2012 cars, as well as adding remote start and global window controls. I will also be showing many of the other features available in the app that I did not add to my car, or are not applicable for my S60. Stay tuned!

2013+ Shifter Retrofit Project Pt. 2 - Reconstruction and Installation

This is the second part of replacing the shifter, if you have not seen part 1 yet, I highly recommend starting there!

Installation of the new parts is like the teardown but in reverse. One thing to note is that you can not attach the knob and boot before attaching them to the shaft of the shifter! The design of the clips is made to that it retains the knob and boot when it is attached. During installation, place the boot on the shaft (do not clip it in until the end, especially the lower clips at the base of the boot) and then attach the knob and move it down into position. Make sure you have the knob trigger pressed in when pushing down, and test to make sure the movement is working. From there, press the top of the boot into place, this requires a good bit of force, as once these clips attach, the whole upper assembly is locked in.

From here, move the wire into the provided zip tie loop and move it around the base and plug it in. I made the mistake of clipping in the boot base clips and had to carefully undo them to move the wire into the correct location. Once the cable is in place, press down on the corners of the boot to lock it into place.

Now we will begin the process of installing the shifter into the car!

For this, I used p.ricos guide on the Swedespeed forums.

As a secondary resource, I also had handy a copy of the PDF from Vida which shows techs the process of removal.

The process is actually very easy, and may seem daunting. The tools you will need are minimal, and the hardest part is just shimmying many of the parts in and out of position. Personally this job took me around an hour and a half, and I had one other person help me.

Mid-removal of the old shifter.

Following the guide makes the process a breeze, and always make sure to test everything before re-assembly! There is a small connector on the side that if not plugged in will not trigger the brake release. Overall I am very happy with this upgrade, and the new shifter looks and feels great. Its even quieter than the old one which is a plus! My next project will most likely be my venture into the world of using V.DASH so stay tuned! I will leave the comments open on this post, so feel free to ask questions here of in the respective SwedeSpeed forum post.

2013+ Shifter Retrofit Project Pt. 1 - Preparation and Disassembly

For the P3 chassis there were 2 different shifter designs that were used throughout the years. For the 2011 and 2012 S60s, they came with the older “gated” style shifter. While there is nothing inherently wrong with the design, it is dated and somewhat clunky in comparison to newer shifter designs. One of the many benefits of owning a P3 is that many of the parts from newer models are plug and play on older models, meaning I can upgrade to newer styles for cheap. The availability of parts from online also helps with this process. For my retrofit, I decided I wanted to do a full Polestar shifter upgrade, with the stitched boot and Polestar stamped shifter. While I could go out and track down an assembly from a wreck Polestar, it is much easier to source all the parts separately.

It is worth noting there are 2 different shifter connector types. Some use a ribbon cable, and later ones were updated to a 2-pin connector. The ribbon cable can be used to install the glass Polestar shifter, but for all other cases it is better to use the 2-pin as it is stronger.

For this project I used these 3 parts:

31367921 - This is the full shifter assembly, with the stock boot and shifter. I got mine for $80 from eBay off a wrecked car. The condition of the shifter and boot were 7/10, but this wont matter since they are being removed.

31454423 - This is the new Polestar shift knob, can be found at Viva Performance and many other online retailers. (I even found it on Amazon)

31367827 - This is is the Polestar shift boot with blue stitching.

For reference, here is the current shifter, vs the updated design.

Credit to P.Rico on Swedespeed for the image.

The first step was to source the entire shifter assembly, which was easy. Mine was a fully standard S60 shifter, with a leather boot and gloss black knob. The unit was fairly dirty and had some damage on the silver trim around the knob.

Cleaning the assembly. It had lots of grime on many of the crevices, most likely a smoker car.

The next step was dissembling the boot and knob. This process was not documented anywhere on the forums, but the process is fairly simple. If you are doing this yourself you are going to need two people for the knob.

Step 1. Remove the boot from the outside of the assembly. For this example I removed the boot from the plastic retainer, if you want to save the original boot, push the black tabs in on each side and push up!

Step 2. Moving the boot downward. In this step you will pry the two tabs on the white circle clip outwards. When they are out, push the boot downward away from the knob.

A small flathead was used on each side to pry the boot clips outward.

Step 3. The hardest part is removing the knob from the shifter ‘shaft’. The knob is secured with 2 clips on each side. Both sides, at the top, will have to be pried outward away from the knob. While doing this, the second person will have to squeeze the button on the knob and pull upwards.

Step 4. The cable can be unplugged from the base of the assembly and snaked up through the clips holding it in. From here all of the cosmetic parts of the shifter will be loose and easy to remove.

The black piece shown below the boot goes in between the knob and boot to hold the boot in place.

In part 2 we will be covering installing the new cosmetic pieces onto the shifter assembly.

Archive

-

2025

- Dec 15, 2025 11-16 Ford Super Duty Remote Start Ultimate DIY Guide Dec 15, 2025

- May 5, 2025 Volvo 700 Series In-Tank Fuel Sender Assemblies - Whats the deal? May 5, 2025

- Apr 28, 2025 Store Update: Shipping Rates and Carriers Apr 28, 2025

- Jan 1, 2025 Cash for Clunkers and Todays Car Marketplace - A Mathematical Analysis on Why Cash For Clunkers Doesn't Matter Anymore. Jan 1, 2025

-

2024

- Nov 25, 2024 11-16 Ford F250 / F350 Super Duty - Definitive Flow-Through Center Console Install Guide Nov 25, 2024

- Jul 30, 2024 13-16 F250 Steering Wheel and Audio Control Upgrade / Retrofit Guide for Dummies Jul 30, 2024

- Mar 13, 2024 Misc. Project - Volvo P3 Desk Chair Mar 13, 2024

- Jan 16, 2024 The Definitive P2 XC90 External Transmission Cooler Writeup Jan 16, 2024

-

2023

- Aug 8, 2023 TFT Display with P3Tool Guide Aug 8, 2023

- Aug 4, 2023 Facility Upgrades and Updates Pt. 2 - Tow Dolly Aug 4, 2023

- Mar 27, 2023 Facility Upgrades and Updates Pt. 1 - John Deere 165 Hydro Restoration Mar 27, 2023

-

2022

- Sep 27, 2022 P3Tool - Volvo Hacking Takes Its Next Big Step Sep 27, 2022

- Aug 25, 2022 Project Nashville Pt. 3 - MOST Excelent! Aug 25, 2022

- Jun 28, 2022 NordCarolina Shop Update! Jun 28, 2022

- Jun 20, 2022 Project Nashville Pt. 2 - Tech Talk Jun 20, 2022

- May 12, 2022 And I Would Drive 500 Miles - Project Nashville Pt. 1 May 12, 2022

- Mar 14, 2022 On life, cars, and business. Mar 14, 2022

-

2021

- Jul 19, 2021 Volvo 960 Project Pt. 6 - Still Alive Jul 19, 2021

- Mar 12, 2021 Volvo 780 Bertone Project Pt. 2 - Why buying another persons project is the WORST. Mar 12, 2021

-

2020

- Dec 7, 2020 Volvo 780 Bertone Project Pt. 1 - In Over My Head Dec 7, 2020

- Dec 7, 2020 Volvo 960 Project Pt. 5 - Taking my time. Dec 7, 2020

- Sep 11, 2020 A Very Volvo September Sep 11, 2020

- May 15, 2020 960 Project Pt. 4 - End of Spring Almost Summer Updates May 15, 2020

- Feb 3, 2020 960 Project Pt. 3 - Always Remember Your Oil Feb 3, 2020

-

2019

- Dec 17, 2019 Nord Carolina - Starting my own E-Commerce Platform for Volvo Enthusiasts Dec 17, 2019

- Nov 20, 2019 960 Project Pt. 2 - I built it one piece at a time... Nov 20, 2019

- Oct 2, 2019 960 Project Pt. 1 - Diving In Oct 2, 2019

- Sep 20, 2019 1997 Volvo 960 Project Pt. 0 - $800 Worth of Headaches Sep 20, 2019

- Aug 3, 2019 VDASH Pt. 2 - Cloud Based Car Tuning Aug 3, 2019

- Jul 2, 2019 VDASH Pt 2. is coming.... Jul 2, 2019

- Apr 1, 2019 VDASH Pt. 1 - A new tool for a modern Volvo hacker Apr 1, 2019

- Mar 18, 2019 2013+ Shifter Retrofit Project Pt. 2 - Reconstruction and Installation Mar 18, 2019

- Feb 17, 2019 2013+ Shifter Retrofit Project Pt. 1 - Preparation and Disassembly Feb 17, 2019

- Feb 2, 2019 The P3 Common & Uncommon Repairs Documentation Project Feb 2, 2019

-

2018

- Dec 28, 2018 Mini-Post: New side skirt. Dec 28, 2018

- Dec 8, 2018 Driveability and Performance Report: December 2018 Dec 8, 2018

- Oct 8, 2018 Audio Modules & The Return to Boostmoose Oct 8, 2018

- Jul 28, 2018 The Final Report: 850R Beauty Shots Jul 28, 2018

- Jul 17, 2018 Mid-July Summer Update Jul 17, 2018

- May 15, 2018 Summer Progress Update May 15, 2018

- Apr 1, 2018 850R - Stage 0 Dreams Pt. 2 Apr 1, 2018

- Mar 18, 2018 850R - 960 Throttle Body Upgrade pt. 1 Mar 18, 2018

- Mar 14, 2018 850R - Seat Restoration Mar 14, 2018

- Jan 18, 2018 S60R - Wrap Repair + Driving the Eastern Shore Jan 18, 2018

- Jan 1, 2018 S60R - Vinyl Wrap Jan 1, 2018

-

2017

- Dec 4, 2017 850R - Better and Brighter Tail Light Installation Dec 4, 2017

- Dec 4, 2017 S60R - Holiday Charity Laps at Virginia International Raceway Dec 4, 2017

- Nov 16, 2017 850R - Junkyard Pulls for Performance & New Rear Lights Nov 16, 2017

- Nov 15, 2017 S60R - Scheduled maintenance.....yawn. Nov 15, 2017

- Nov 3, 2017 850R - Stage 0 Dreams Pt. 1 Nov 3, 2017

- Nov 1, 2017 850R - Firestone Fixes CV Axle while Suspension Nears Completion Nov 1, 2017

- Oct 28, 2017 850R - Axle Removal and CV Boots Halt Progress Oct 28, 2017

- Oct 27, 2017 850R - Air Tool Woes and Broken Brakes Oct 27, 2017